Quality System

Quality System

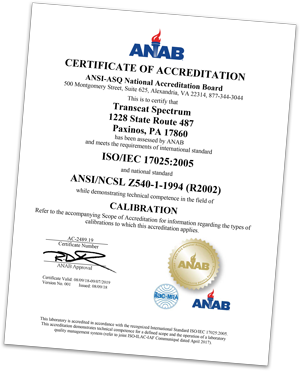

Transcat Biomedical, formerly Spectrum Technologies, quality policy focuses on providing quality test instrument metrology and repair services to all our customers, complete these services in a timely manner and ensure all customer requirements are met or exceeded in every situation. Transcat Biomedical employees continuously strive to meet the quality objectives established by the organization and continuously improve the effectiveness of the Quality Management System in order to provide our customers with the highest level of customer service and satisfaction. Transcat Biomedical’s Paxinos lab is now accredited to ISO/IEC 17025:2017.

Lance Hopkins, Quality Representative,

lance.hopkins@transcat.com

570-216-5665

Calibration is the comparison of an instrument’s performance to a standard of known accuracy. It is the determination of the instrument’s deviation from a nominal value which may result in an adjustment, a correction factor, or an exclusion. Properly calibrated instruments provide confidence that the products/services provided are of the highest quality. Calibration increases production, ensures consistency in measurements & products, and optimizes resources.

What Transcat Biomedical Customers Are Saying

Easy to work with professional & courteous, will definitely continue to use Transcat Biomedical as our preferred vendor for test equipment calibration.

Calibration Quality Facts

- Proper standards are used that maintain a 4:1 (25% uncertainty) ratio between the standard and unit under test.

- Proper calibration methods are employed. Everything cannot be calibrated on-site. Environments must be controlled and compensated as necessary. Proper testing methods are utilized for the various instruments tested.

- Calibration certificates are issued.

- Calibration data is supplied for ALL out of tolerance conditions.

- A quality system program in place, preferably a certified program.

- Instrument repair capabilities are available, including most obsolete test equipment.